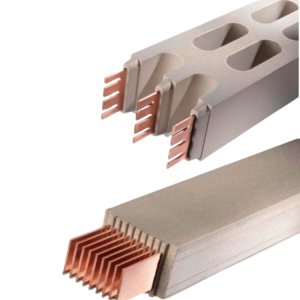

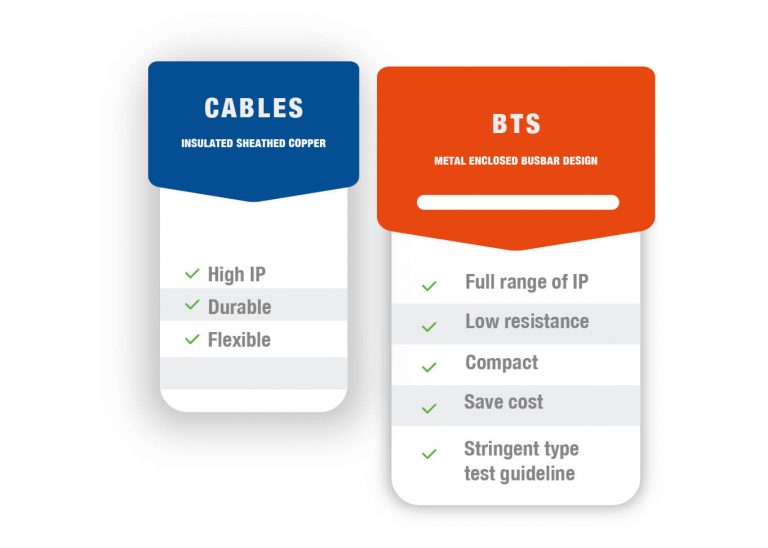

LA/LB TECO Cast Resin Busbar Trunking System (a.k.a Busway, Bus Duct) is built with excellent features of electrical characteristics and mechanical strength, fire and waterproof, anti-corrosion, compact size, easy installation and most importantly maintenance-free.

Busbar Trunking System

LT Line I

LT Line I Busbar Trunking System (a.k.a Busway, Bus Duct) is a reliable and efficient electrical distribution system with sandwich construction and superior performance. It is a safe and robust power distribution system with high electrical efficiency, low voltage drop, and high mechanical strength.

Applications

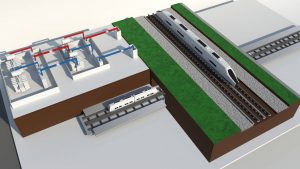

Metro Application Considerations

Metro Application Considerations

- Service Continuity

- Model Availability

- Halogen-free

- Low Voltage drop

- Low Maintenance Frequency

- Low Electromagnetic Field Emission

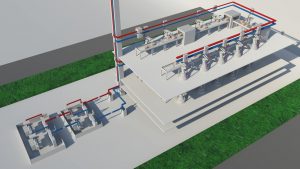

Industry Application Considerations

Industry Application Considerations

- Service Continuity

- Flexibility to evolve/expand

- Halogen-free

- Low Voltage drop

- Low Maintenance Frequency

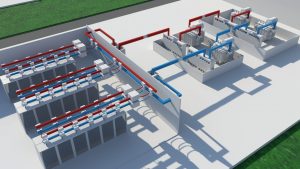

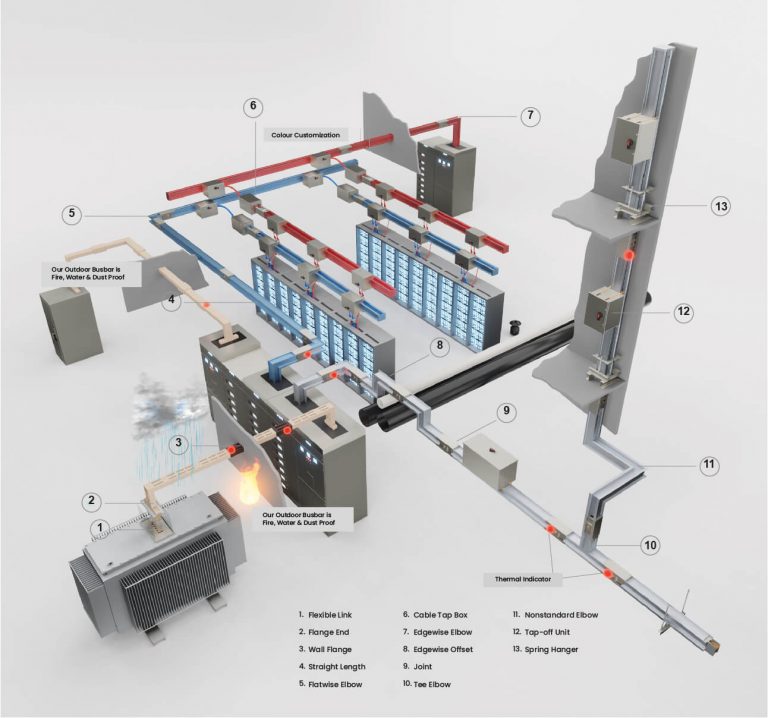

Data Center Solution

Data Center Solution

- Service Continuity

- Halogen-free

- Flexibility to evolve/expand

- Customisable Colour

Hospital Application Considerations

Hospital Application Considerations

- Service Continuity

- Halogen-free

- Low Voltage drop

- Low Electromagnetic Field Emission

Commercial Application Considerations

Commercial Application Considerations

- Service Continuity

- Flexibility to evolve/expand

- Halogen-free

- Low Voltage drop

- Low Maintenance Frequency

Residential Application Considerations

Residential Application Considerations

- Service Continuity

- Halogen-free

- Low Maintenance Frequency

Data Centre Busway System

Manufacturer of Power Distribution Systems since 1980s

- The only brand that conducts factory routine test in Singapore

- Provide local technical and replacement/repair support with the shortest lead time

- Type tested and certified to IEC 61439-6 standard

- Quality assured with 3rd party (KEMA) surveillance

Strong after-sales services

Support you with individualized consultation and tailor our solution to suit your needs and in compliance with the relevant standards

- Be personally accountable for our desired results. We will take responsibility for every aspect of our products and services.

- Be proactive. We stay ahead of the curve with customers, anticipating problems and acting in advance to solve them.

Audit

Reduce Risks and Improve Reliability

Our engineers help assess your sites, identify safety and efficiency issues of your critical installations. We will help reduce risk, improve reliability for your electrical distribution needs, and optimize your energy usage while pointing the way to your digital journey.

Maintenance

Ensure Equipment Peak Performance

Helping you keep mission-critical infrastructure operating at maximum efficiency and optimal performance is our main goal. Our support services provide flexibility for all aspects of your electrical distribution needs.

Training

Get Tailored Training Solutions

Our technical training solutions can enhance your team’s technical competencies in electrical safety and distribution.

Spare Parts

Get the Right Parts at the Right Time

Don’t run the risk of extended electrical downtime and take advantage of our local assembly facility for all your spare part needs.

Services

Engineering excellence

Drawing is ready for production in maximum of 7 working days once requirements are fully provided.

Southeast Asia (SEA) Expertise

Achieved essential field experience

We have successfully participated in various market segments, including Airports, Wafer Fabrication Plants, Hospitals, and more. We support our projects with a Pan SEA approach based on best practices.

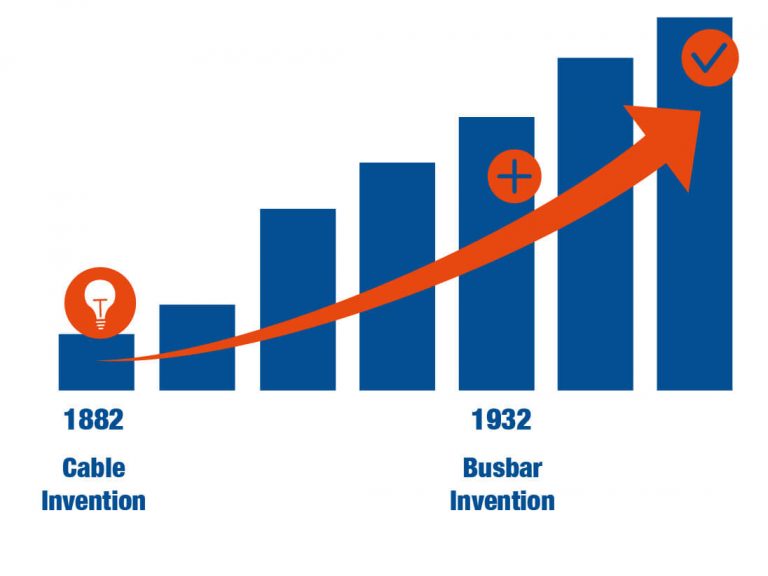

History of Busbar Trunking System Invention

Busbar trunking system, first introduced in 1932, solving the automation industries needs for flexible power distribution system.

How Busbar Trunking System became a popular choice in the power distribution market?

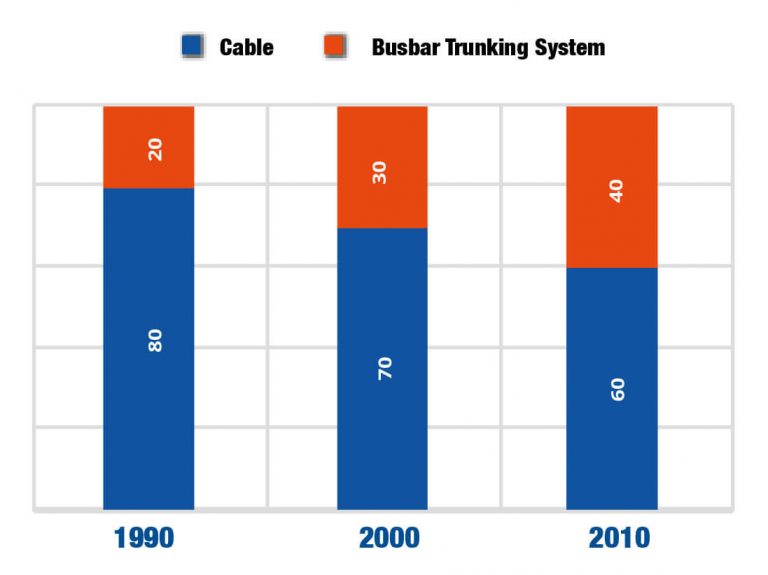

Busbar Trunking System Adoption in Singapore

Busbar Trunking System accounts for >50% in power distribution of data centres, government industrial, and healthcare projects

What is the typical warranty coverage of Busbar Trunking System?

Typical warranty coverage is 12 months, coverage on manufacturer defects.

What is the maintenance frequency of Busbar Trunking System?

Busbar Trunking System is designed to be maintenance-free. As a recommendation, the maintenance frequency will be once a year or after any fault occurrence.

What is the solution for Outdoor Busbar Trunking System installation?

Cast resin type Busbar Trunking System with IP68 rating is recommended for Outdoor Application.

Can Busbar Trunking System be installed underground?

No, due to maintenance requirement.

What is typical leadtime of Busbar Trunking System?

10-12 weeks upon approval & confirmation of shop drawings, Factory Routine Test Conducted in Singapore.

How fast can we receive the add on items as the project is closing soon?

Typical short length or accessories, lead time is 5 to 14 working days (Exclude freight logistics lead time).

Is the certification validity & range traceable?

Cerification is only traceable for full type test under Kema with Kema Keur, Asta with Asta Diamond or UL with UL Classified.

Is Tai Sin Busbar able to integrate with other Busbar Trunking Systems?

No, Busbar Trunking system is a proprietary design system, hence integration will have to be of the same make & model in order to be compatible.

What is the critical test to ensure Busbar Trunking System complied?

There are 3 levels of test to ensure integrity of the busbar trunking system.

- Level 1 – Type Test by accredited test laboratories (One-time type test to ensure compliance to guideline standards – IEC 61439-6)

- Level 2 – Factory Acceptance / Routine Test (Factory internal quality routine test: Meg etc)

- Level 3 – Site Acceptance Test (Conducted during installation phase)